NO1 Miniature Pump Manufacturer in China

Your Trustful Miniature Pumps Manufacturer

BODENFLO Company Display

Are you in search of a reliable and versatile miniature pump solution?

Look no further. Shenzhen Boden Technology Development Co., Ltd. (Brand: BODENFLO) is China’s TOP manufacturer, specializing in miniature diaphragm and micro piston pumps. Our product range includes micro air pumps, miniature vacuum pumps, and micro liquid pumps, each available in hundreds of standard specifications. With over a decade in the industry, we also offer customized services and solutions tailored to your needs.

Why trust us?

We hold ISO9001 certification, ensuring our commitment to quality and innovation. All our products comply with CE and ROHS standards, and our core patents stand as a testament to our reliability and expertise in the micro pump sector. Choose BODENFLO for a trustworthy and efficient micro pump solution.

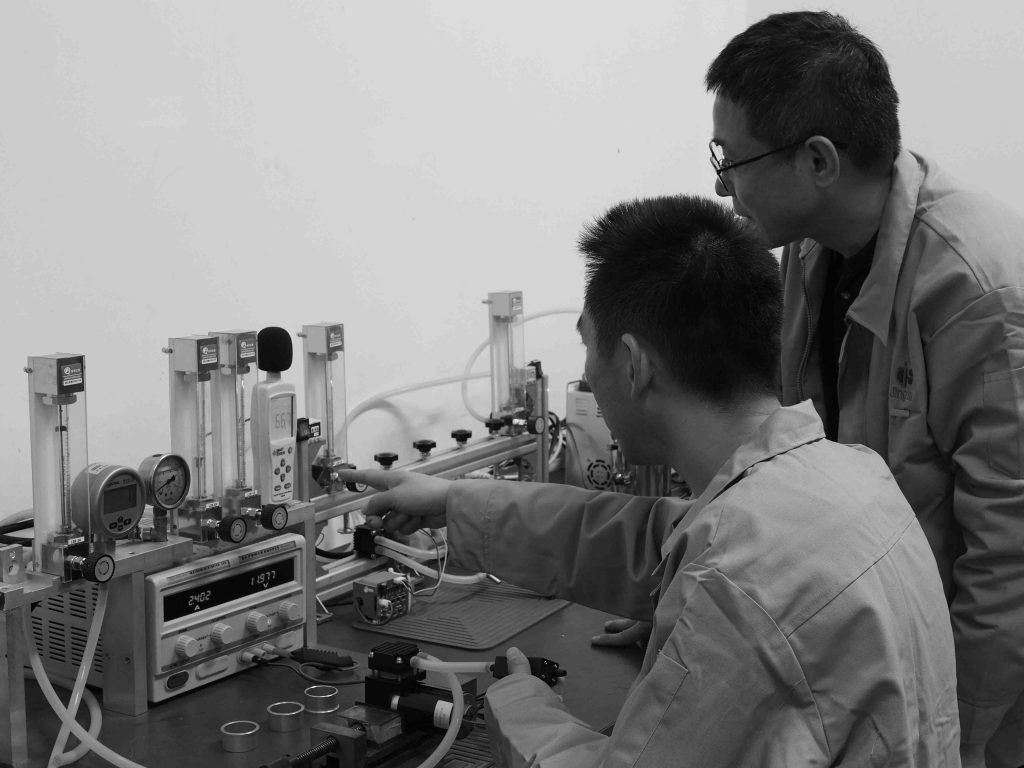

BODENFLO Workshop Display

Discover More - BODENFLO Product Brochures

Miniature diaphragm pumps for pressure and vacuum

Miniature diaphragm vacuum pump brush

45.5×15.5×25.5mm; DC3V/6V/12V; Flow 0.5-1 L/min;Pressure 0.5-1bar; Vacuum -30-50kpa; 24g.

Micro diaphragm vacuum pump brush

31×17×25mm; DC1-5V; Flow 250-550mL/min;Pressure 44kpa; Vacuum -30-45kpa; 16.4g

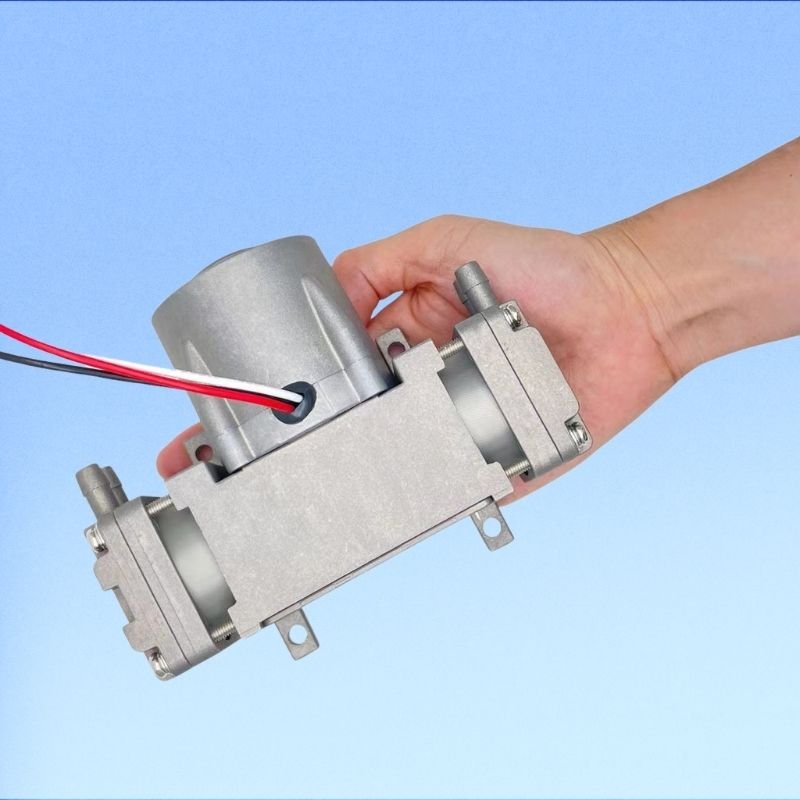

Miniature piston pumps for pressure and vacuum

Micro compressor pump for pressure and vacuum

Miniature diaphragm pumps for liquid and water

Miniature water pump brush

45.5×15.5×25.5mm; DC3V/6V/12V; Water Flow 100-200 mL/min;Vacuum -30kpa; 24g.

miniature 12v water pump brush

55x24x40mm; DC6V/12V/24V; Water Flow 200-500 mL/min;Vacuum -30kpa; 71g.

Miniature diaphragm water pump brushless

53x24x40mm; DC6V/12V/24V; Water Flow 200-500 mL/min;Vacuum -30kpa; 73g.

Miniature electric water pump

76x30x49 mm; DC6V/12V/24V; Water Flow 400-700 mL/min;Vacuum -30kpa; 140g.

Miniature fluid pump brushless

64x30x49 mm; DC6V/12V/24V; Water Flow 400-700 mL/min;Vacuum -30kpa; 120g.

Miniature liquid pump 12V

101x40x72 mm; DC6V/9V/12/24V; Water Flow 1-1.5 L/min;Vacuum -30kpa; 305g.

Miniature pumps for liquids

92x40x72 mm; DC6V/9V/12/24V; Water Flow 1-1.5 L/min;Vacuum -30kpa; 305g.

High Presure Diaphragm water pump

Quality Meets Affordability: ISO9001 Certified, CE and ROHS Compliant Micro Pumps at Competitive Prices

All You Need to Know About Miniature Pumps

Common types of miniature pumps

When it comes to the realm of miniature pumps, two distinct categories stand out: miniature diaphragm pumps and piston pumps. These small yet powerful devices operate based on different principles, offering unique advantages for various applications. In this comprehensive exploration, we uncover the core principles, components, key considerations for purchasing miniature pumps, Advantages of miniature diaphragm and piston pumps, best product application.

Understanding the Principles

Micro Diaphragm pumps and piston pumps are emblematic of precision engineering. Diaphragm pumps leverage flexible diaphragms to create controlled pressure variations, while piston pumps rely on reciprocating pistons to achieve fluid movement. Both mechanisms showcase their prowess in accommodating diverse mediums, making them versatile choices across industries.

Application Requirements

Identify the specific requirements of your application, including flow rate, pressure, and media compatibility. Choose a pump that aligns with these needs.

Size and Portability

Consider the dimensions and weight of the pump to ensure it fits within your setup. Portability might be crucial for certain applications.

Power Efficiency

Look for pumps that offer low power consumption without compromising on performance. This helps reduce operating costs and energy consumption.

Media Compatibility

Ensure the pump is compatible with the type of media you’ll be handling, whether it’s liquids, gases, or a combination of both.

Noise and Vibration

Assess the noise level and vibration produced by the pump. Opt for pumps with quiet operation and minimal vibration, especially for sensitive environments.

Reliability and Durability

Choose pumps from reputable manufacturers known for producing reliable and durable products. Consider factors such as material quality and construction.

Control and Adjustability

Check if the pump offers adjustable settings for flow rate, pressure, and other parameters. This flexibility can be crucial for fine-tuning performance.

Maintenance and Service

Evaluate the ease of maintenance, availability of replacement parts, and the manufacturer’s customer support. A reliable after-sales service is important.

Certifications

Look for pumps that have relevant certifications such as CE, ROHS, and ISO standards. These certifications indicate compliance with quality and safety standards.

Cost-Effectiveness

While cost is a factor, focus on the overall value the pump provides rather than just the initial price. Consider factors like efficiency, lifespan, and performance.

Advantages of Miniature diaphragm & piston pump

Compact Size

Micro diaphragm pumps and micro piston pumps boast a compact design, allowing for easy integration into space-constrained setups without compromising on functionality.

Oil-Free Operation

Both micro diaphragm pumps and micro piston pumps offer oil-free operation, ensuring that the pumped media remains uncontaminated and suitable for sensitive applications.

Low Power Consumption

These pumps are engineered for efficiency, consuming minimal power while delivering reliable performance, making them cost-effective and energy-efficient choices.

Precise Fluid Control

The inherent design of these pumps enables precise fluid control, making them suitable for applications that demand accurate flow rates and consistent performance.

Quiet and Low Vibration

The advanced engineering of these pumps results in quiet operation and minimal vibration, ensuring a conducive working environment and reducing potential disturbances.

Versatile Media Compatibility

Both pump types exhibit excellent compatibility with a wide range of media, whether liquids or gases, making them adaptable to various industrial, medical, and laboratory applications.

Best application of miniature pumps

BODENFLO Micro diaphragm pumps and micro piston pumps find optimal applications in various industries and scenarios. Here are their best applications:

When off-the-shelf solutions don’t meet your specific needs, a customized miniature pump can offer the precision, performance, and reliability you’re looking for. BODENFLO specializes in customizable options, tailoring each pump to meet your exact specifications. This guide will walk you through the steps of customizing your miniature pump with us.

How to Customize Your Miniature Pump: A Step-by-Step Guide

Step 1: Identify Your Requirements

First and foremost, have a clear understanding of your needs. Take into consideration factors like fluid compatibility, flow rate, pressure, and operating environment. Compile all these requirements for reference.

Step 2: Initiate a Consultation

Reach out to our team of experts. Share your requirements, and we’ll help you identify the best customization options to consider. You can contact us via Alibaba, our B2B website, or directly through email for a more personalized discussion.

Step 3: Review Customization Options

We offer a plethora of customization options ranging from materials like EPDM, FKM, and PTFE to various types of motors and electrical connectors. Review these options and consult with our team for guidance.

Step 4: Prototyping

We offer a plethora of customization options ranging from materials like EPDM, FKM, and PTFE to various types of motors and electrical connectors. Review these options and consult with our team for guidance.

Step 5: Finalization and Production

After successful prototyping and any necessary revisions, your customized miniature pump will go into production. Our quality assurance team will oversee the manufacturing process to ensure each unit meets your exact specifications.

Troubleshooting Common Mini Pump Issues

Navigating through operational hitches is crucial for maintaining the longevity and effectiveness of your miniature pump. In this guide, we’ll explore some of the most common issues that users face with miniature pumps, their possible causes, and how to resolve them.

Issue 1: Reduced Flow Rate

Possible Causes:

Clogged Filter

Obstructed inlet/outlet

Worn-out diaphragm or valves

Solutions:

Inspect and clean the filter regularly to ensure it’s not clogged.

Check the inlet and outlet for any obstructions and clear them.

Replace worn-out parts like the diaphragm or valves to restore the pump’s performance.

Issue 2: Excessive Noise

Possible Causes:

Loose components

Unbalanced motor

Solutions:

Tighten all screws and secure components properly.

Check the motor balance; if needed, consult a technician to fix it.

Issue 3: Pump Overheating

Possible Causes:

Incorrect voltage supply

Excessive run time

Lack of cooling in the operational environment

Solutions:

Ensure the voltage supply matches the pump’s specifications.

Limit continuous operation as per the user manual guidelines.

Provide sufficient cooling to keep the pump’s temperature within an acceptable range.

This paragraph to cover some of the most prevalent issues faced by miniature pump users. Regular maintenance and timely troubleshooting are critical for the optimal functioning of your pump. For further assistance, feel free to consult your manufacturer’s technical support team.

Custom Miniature Pumps with Easy

At BODENFLO, We turn complex Into Simple! Follow the following 3 steps to start today!

Tell Us What You Need

Tell us as specific as possible of your needs, provide the parameter, reference picture and share your idea.

Get Solution & Quote

We will work on the best solution according to your requirements, the specific quote will be provided within 12 hours.

Approve for Sample/Mass Production

We will start production after getting your approval and deposit, and we will handle the shipment.

GET AN INSTANT QUOTES

Contact us to get a free quote and more expertise about custom miniature diaphragm pump and micro piston pump. Your project will meet a right solution with BODENFLO.